Your Vision, Our Expertise

Unleash the Power of Permanent Magnets

Permanent Magnets are the driving force behind countless innovations, from electric vehicles to wind turbines, medical devices and more. At Magnequench, we realize its full potential with our custom design and manufacturing capabilities.

Design the future, your way.

Magnetic Innovation Across Industries

We don’t just build magnets, we engineer magnetic breakthroughs. Drawing on our deep expertise, we tackle the toughest challenges in magnet properties and functionality.

Whether you need a custom component or an intricate system, we design solutions that are precisely tailored, robustly functional, and built to last across all industries.

Customized Magnets

Meeting Exact Specifications

At Magnequench, our advanced manufacturing processes and rigorous quality control ensure your magnets meet your specific dimensional and tolerance requirements.

We conduct in-house testing and simulations to validate your solution performs exactly as needed. From flux density to coercive force, we speak the language of magnets needed for optimal performance.

Your Trusted PM Manufacturer

Leading Magnet Solutions

As specialists in magnets, we understand the escalating demands for their properties and capabilities. Our extensive know-how and products encompass a variety of magnet types due to the versatility of our MQ1™ technology.

Bonded Rare-Earth Permanent Magnets

Neodymium (NdFeB)

Our primary focus, known for high strength and compact size, ideal for motors, sensors, and other high-performance applications.

Samarium Cobalt (SmCo)

High temperature resistance and stability, suitable for harsh environments and aerospace applications.

Ceramic Ferrite

Cost-effective option with moderate strength, used in speakers, motors, and medical devices.

Bonded Magnets & Hot Deformed Magnets

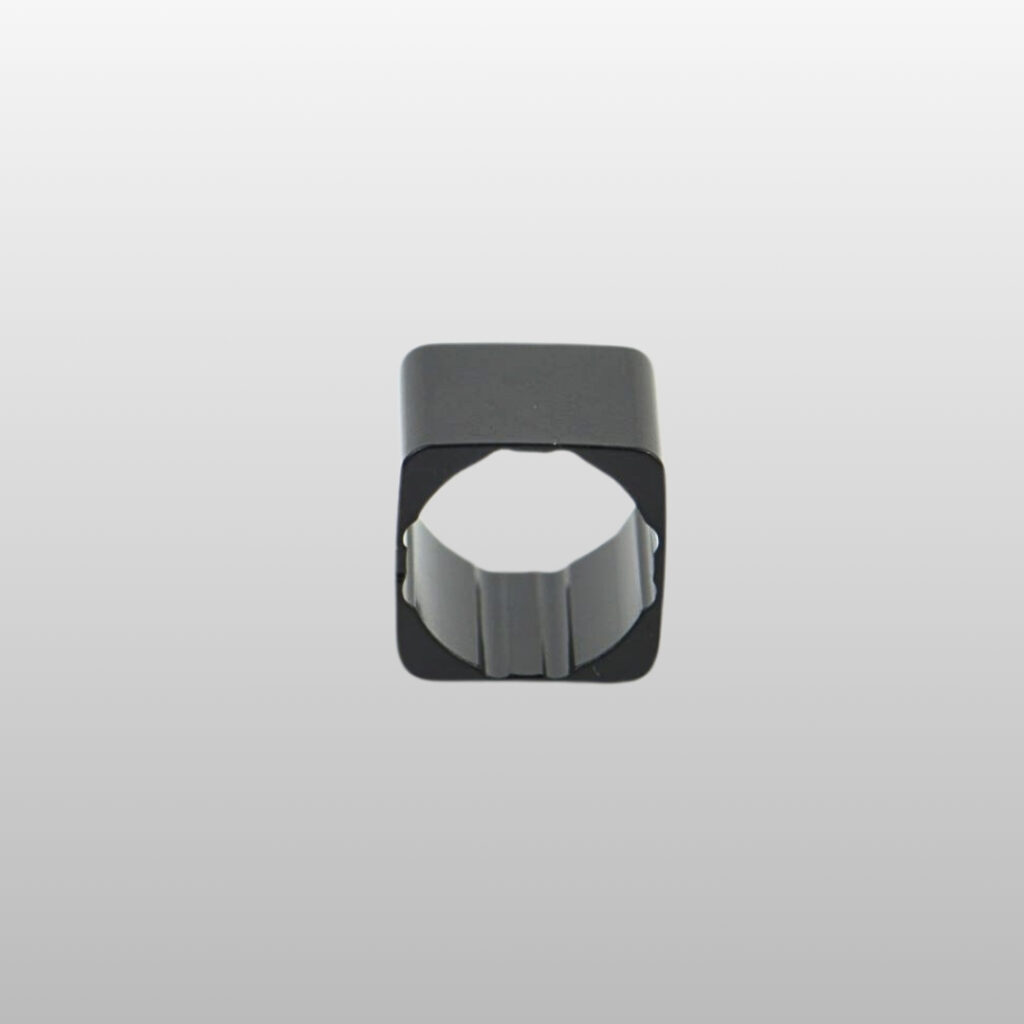

Bonded Magnets

Composed of magnetic powder mixed with a binder, offering flexibility in shapes and sizes, ideal for complex geometries and cost-sensitive applications.

Hot Deformed Magnets

Dense and high-strength magnets created by heating and pressing under pressure, used in demanding motor and industrial applications.

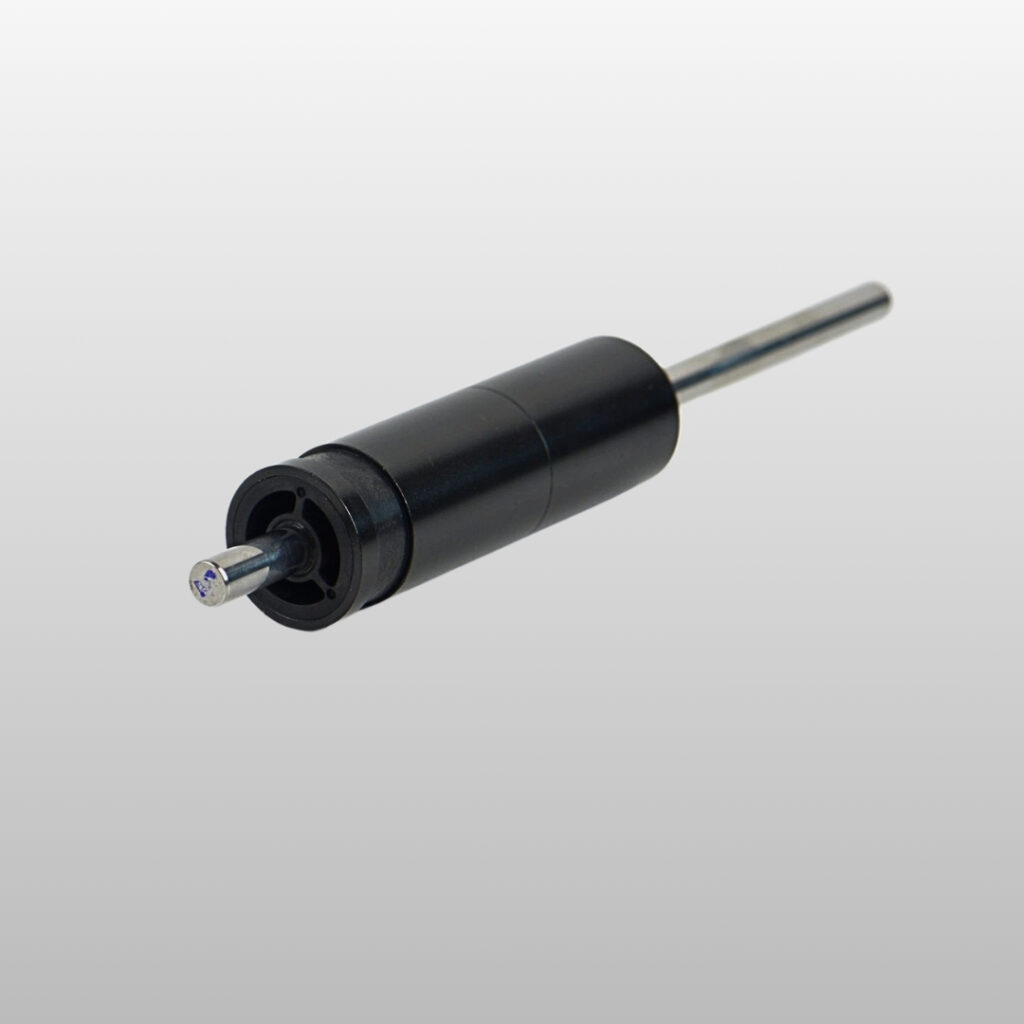

Magnet Assemblies For Specific Needs

Our advanced magnet technology offers customizable magnet assemblies, catering to your unique application needs.

These pre-engineered solutions integrate magnets with other components like housings, brackets, and sensors.

Customers can expect optimized performance for specific application, simplified design, reduced costs and faster time to market.

Extensive Magnet Know-How

Permanent Magnet Grades

Each material type comes in various grades with different magnetic properties like strength, temperature resistance, and cost.

Shapes and Sizes

Magnequench offers a wide range of standard and custom shapes and sizes for diverse applications.

Coatings and Treatments

Various coatings and treatments are available to enhance corrosion resistance, improve adhesion, or meet specific requirements.

SUPPORT AT EVERY LEVEL

Custom Assemblies

Integrating magnets into assemblies and systems is a complex task. We provide comprehensive support to our clients through every step of our manufacturing process. Design your assembly, your way.

Blower Motor

Assemblies can possess immense potential for optimization.

Our commitment to extracting the best out of every component means elevating assemblies, like blower motors, to a new level of performance.

Enhanced-power blower motors, same magnetic base material - in this task we are the perfect partner.

And we keep our promise: opting for the next higher class in the hard-ferrite spectrum and the magnetization's definition as 4- or 6-pole.

Water Pump Motor

With technical expertise and innovative ideas, we make it possible to significantly improve the performance of the previously used water pump.

Maximum performance while utilizing the existing design, simultaneously using the rotor as an impeller: not an easy task that our customer faced with his water pump.

By changing the magnetization, positioning it in the rotor and sealing it against contact with water, our engineering team succeeded in finding a solution.

Plastic-bonded SmFeN magnets

Plastic-bonded SmFeN magnets have a significant advantage: Their geometries can be customized to fit the application.

This is done through injection molding processes.

Plastic-bonded SmFeN magnets have a much higher magnetic performance than hard ferrites. With an equally complex range of shape options, they are mechanically resilient and almost any magnetization level can be chosen.

SmFeN magnets are corrosion-resistant and have very low aging at high temperatures.

Magnify Your Performance

Partner Magnequench

In today’s world, a commitment to sustainability is crucial.

Magnequench shares this value, prioritizing environmentally friendly practices and developing solutions that minimize environmental impact.

Our team of experts works closely with you to design magnet motor solutions that seamlessly integrate with your specific needs and application requirements.

Get comprehensive technical support throughout the entire process and implementation.